|

|

|

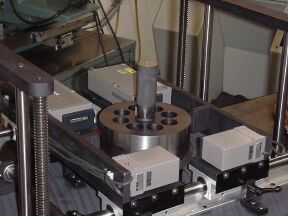

Here we see our Double Laser Fixture. This fixture was built to measure the diameter of a section of rubber that was molded onto a part. Due to the size of the part, 120mm, we decided to measure this diameter to use two laser micrometers. We designed this fixture with the idea in mind that we had to be able to measure the entire area of molded rubber. We accomplished this by allowing the fixture to move the lasers up and down, in and out, and be able to rotate the part.

The first picture shows a good overall view. In this picture we see a sample part, the lasers, the handwheels, and the carriage. The reason this fixture has three handwheels is that there are many places which needed to be measured. The uppermost handwheel moves both lasers in and out at the same time. One reason for this is to make the lasers adjustable. The slides, upon which the lasers move, are also equipped with a friction lock, which allows the lasers to maintain their position once they are calibrated.

Another handwheel rotates the part as it is being checked. This helps to check the roundness of the part. As it does this, it doesn't matter if the part is located perfectly on center. The manner in which the lasers are setup eliminates this problem.

The last handwheel moves the carriage, which includes the lasers but not the part, up and down. This allows the lasers to measure the part in different locations.

The middle picture shows a close up of the lasers with a master in place of the part. The master is a part which is ground to a known diameter so it can be used to calibrate the lasers.

The bottom picture shows the display unit for the measurement of the lasers (top) and the display for the location of the Z axis height (up and down measurement).